RAK17000 Quick Start Guide

Prerequisite

What Do You Need?

Before going through each and every step on using the RAK17000 WisBlock Motor Control Module, make sure to prepare the necessary items listed below:

Hardware

- RAK17000 WisBlock Motor Control Module

- Your choice of WisBlock Base

- Your choice of WisBlock Core

- USB Cable

- Li-Ion/LiPo battery (optional)

- Solar charger (optional)

- DC Motor or Stepper Motor

Software

Arduino

- You need to download and install Arduino IDE.

- To add the RAKwireless Core boards on your Arduino Boards Manager, install the RAKwireless Arduino BSP.

Product Configuration

Hardware Setup

RAK17000 is a WisBlock Motor Control Module that extends the WisBlock system to be used on controlling motors. It has a dual H-bridge configuration motor driver that can support two DC motors or one stepper motor. It can get power from the battery of the WisBlock Base or externally via the RAK17000 terminal connector. By setting the right jumper on the 3-pin header on the side of the terminal connector, you can select where you want to get the power source. It can allow up to 1.5 A per channel, but thermal management must be implemented.

For more information about RAK17000, refer to the Datasheet.

Motor Driven by the WisBlock Battery

- Batteries can cause harm if not handled properly.

- Only 3.7-4.2 V Rechargeable LiPo batteries are supported. It is highly recommended not to use other types of batteries with the system unless you know what you are doing.

- If a non-rechargeable battery is used, it has to be unplugged first before connecting the USB cable to the USB port of the board to configure the device. Not doing so might damage the battery or cause a fire.

- Only 5 V solar panels are supported. Do not use 12 V solar panels. It will destroy the charging unit and eventually other electronic parts.

- Make sure the battery wires match the polarity on the WisBlock Base board. Not all batteries have the same wiring.

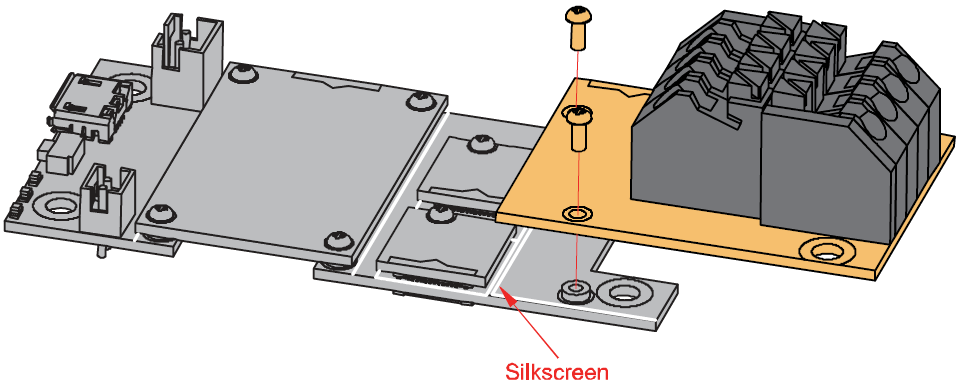

You need to set a header jumper and short VM and BAT to enable power from the battery of the WisBlock module. You can connect up to two DC motors by using channels A and B. To use channel A, connect the DC motor on A1 and A2. To use channel B, connect the DC motor on B1 and B2. You need to use both channels if you are driving a stepper motor.

Figure 1: RAK17000 Powered by WisBlock Battery

Figure 1: RAK17000 Powered by WisBlock BatteryMotor Driven by the External VIN

You need to set header jumper and short VM and VIN to enable power from the external power source. The external power source can be a different battery pack or an independent DC power supply. Connect this power source to the supply voltage terminals VIN and GND of RAK17000 that can allow the voltage range from 2.7 V to 10.8 V. Once done on the setup, you can connect up to two DC motors by using channels A and B.

To use channel A, connect the DC motor on A1 and A2. To use channel B, connect the DC motor on B1 and B2. You need to use both channels if you are driving a stepper motor.

Figure 1: RAK17000 Powered by External Voltage Source

Figure 1: RAK17000 Powered by External Voltage SourceAssembling and Disassembling of WisBlock Modules

Assembling

The RAK17000 module can be mounted on the IO slot of the WisBlock Base board, as shown in Figure 3. Also, always secure the connection of the WisBlock module by using compatible screws.

Figure 1: RAK17000 mounting connection to a WisBlock Base module

Figure 1: RAK17000 mounting connection to a WisBlock Base moduleRAK17000 Connector Crimping Mechanism

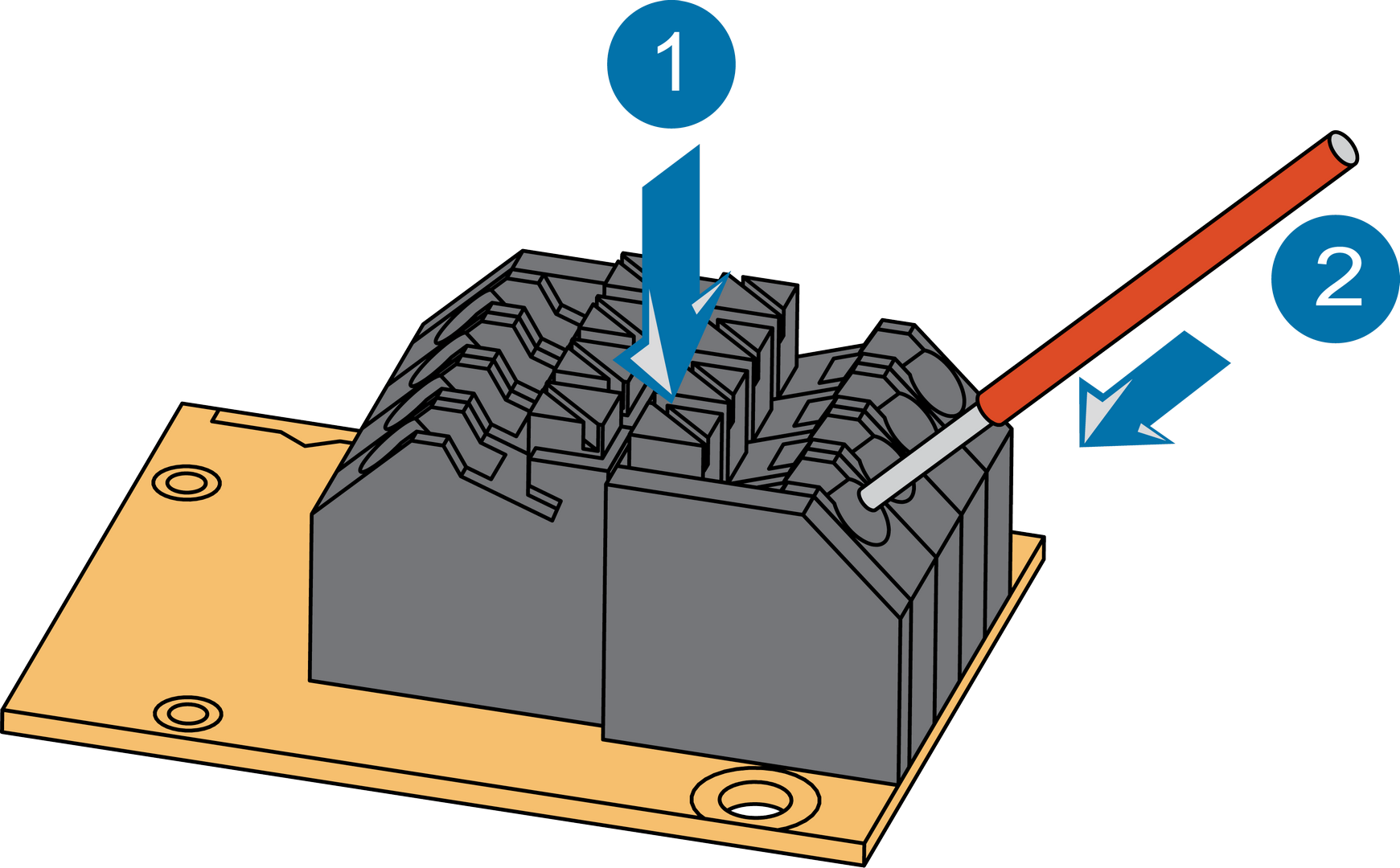

The RAK17000 features a fast-crimping terminal connector to simplify and ensure the wiring process on the fields. The fast-crimping terminal can support cable with a width between 20 AWG to 24 AWG. The usual stripping length is around 6 to 7 mm.

As shown in Figure 4, during the crimping process, you should first press down and maintain the spring head of the crimping terminal firmly, then insert the stripped cable head into the corresponding connector’s hole. Once inserted correctly, release the spring head, and the crimping process is completed.

Figure 1: RAK17000 Module Connector

Figure 1: RAK17000 Module ConnectorDisassembling Procedure

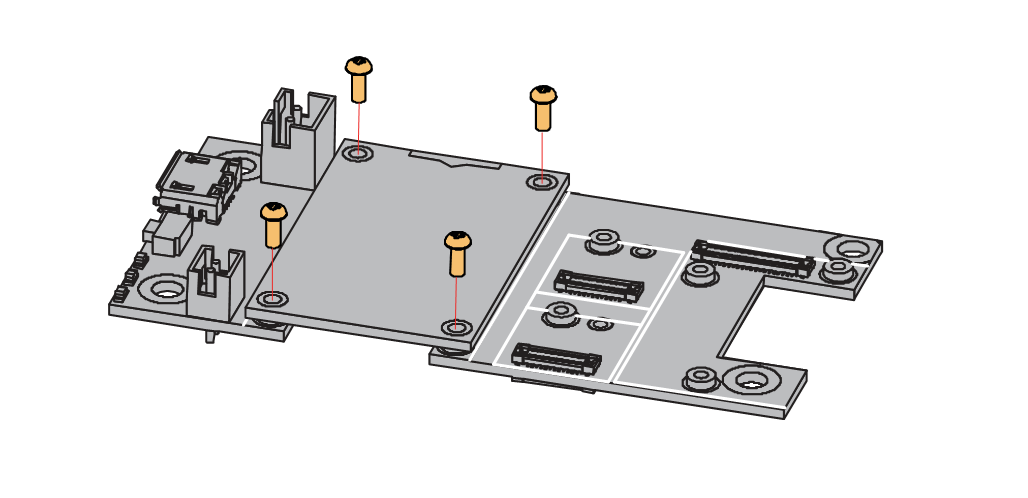

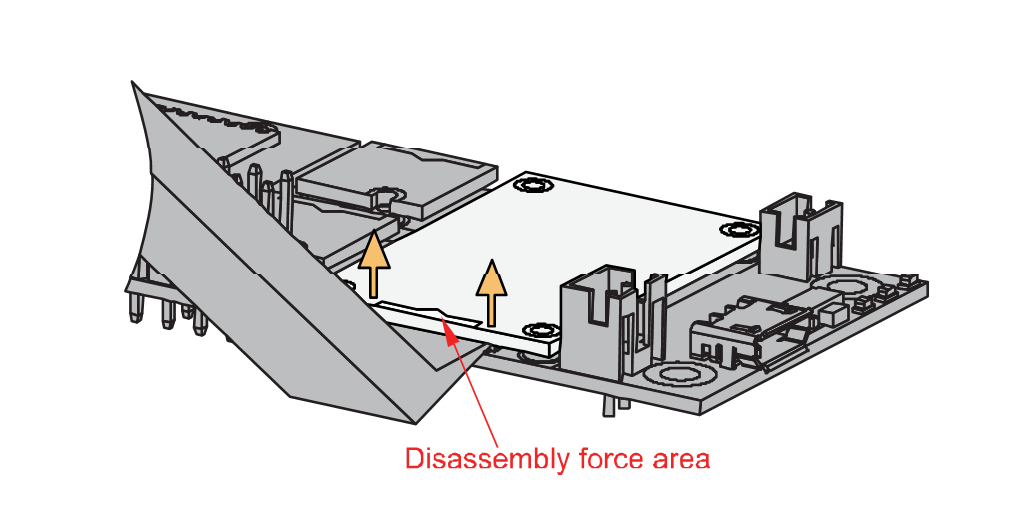

The procedure in disassembling any type of WisBlock modules is the same.

- First, remove the screws.

Figure 1: Removing screws from the WisBlock module

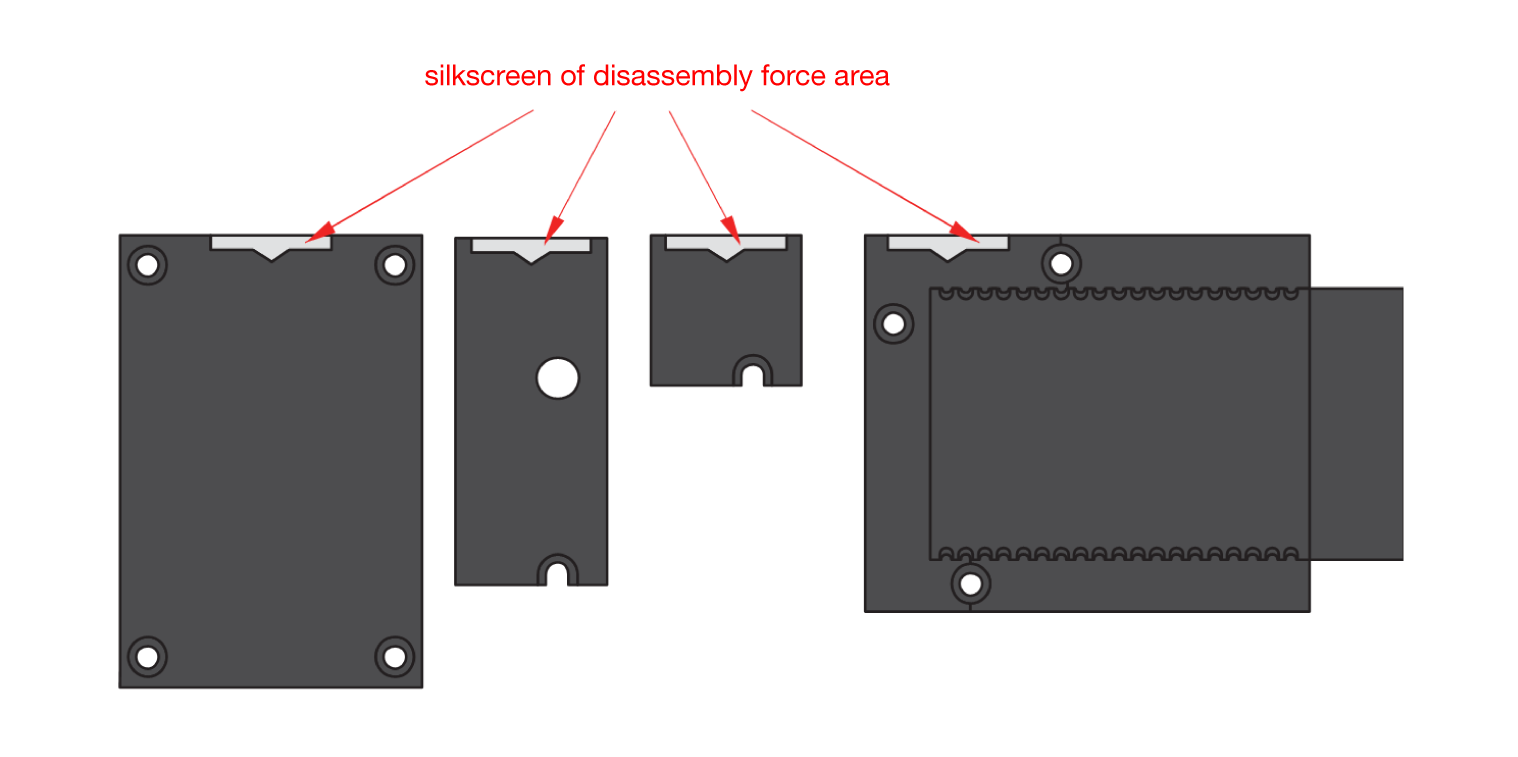

Figure 1: Removing screws from the WisBlock module- Once the screws are removed, check the silkscreen of the module to find the correct location where force can be applied.

Figure 1: Detaching silkscreen on the WisBlock module

Figure 1: Detaching silkscreen on the WisBlock module- Apply force to the module at the position of the connector, as shown in Figure 8, to detach the module from the baseboard.

Figure 1: Applying even forces on the proper location of a WisBlock module

Figure 1: Applying even forces on the proper location of a WisBlock moduleIf you will connect other modules to the remaining WisBlock Base slots, check on the WisBlock Pin Mapper tool for possible conflicts.

Now, you can connect the battery and USB cable to start programming your WisBlock Core.

Software Configuration and Example

These are the quick links that go directly to the software guide for the specific WisBlock Core module you use:

- RAK17000 in RAK4631 WisBlock Core Guide

- RAK17000 in RAK11200 WisBlock Core Guide

- RAK17000 in RAK11310 WisBlock Core Guide

RAK17000 in RAK4631 WisBlock Core Guide

Arduino Setup

After doing the hardware setup, this example code will work both for WisBlock battery-powered motor or an external power source. This will control the DC motors connected in channel A and channel B and make it spin clockwise then counterclockwise direction repeatedly.

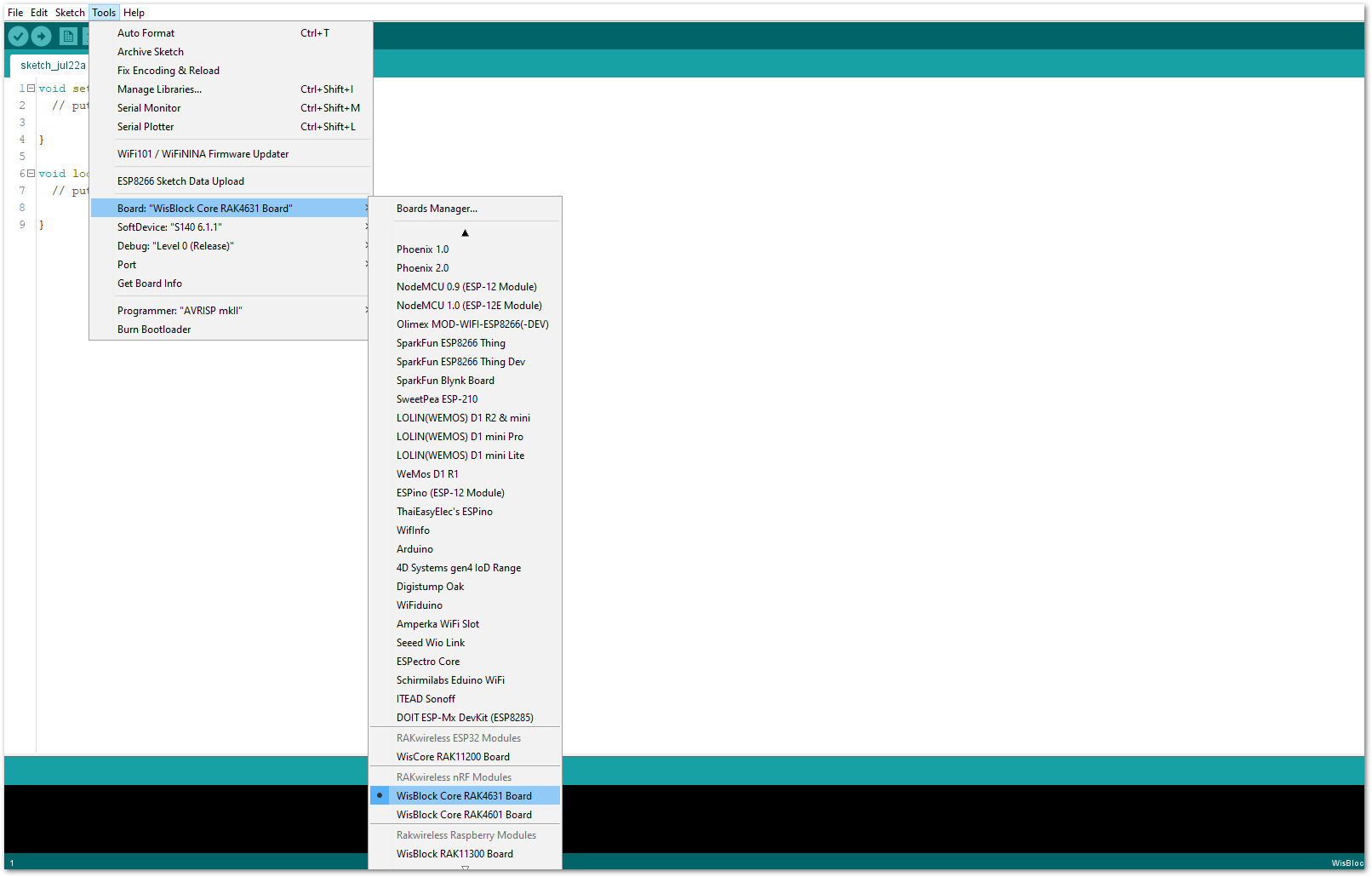

- First, you need to select the RAK4631 WisBlock Core.

Figure 1: Selecting RAK4631 as the WisBlock Core

Figure 1: Selecting RAK4631 as the WisBlock Core- Next, copy the following sample code into your Arduino IDE. This example code comes from the RAK17000 WisBlock example repository which controls two DC motors.

Click to view the code

/**

@file RAK17000_Motor_Driver_DRV8833.ino

@author rakwireless.com

@brief Control the two motors for forward and reverse rotation from slow to fast and then from fast to slow.

@version 0.1

@date 2021-5-14

@copyright Copyright (c) 2020

**/

#include <Arduino.h>

#define MOTOR_AIN1 SCK

#define MOTOR_AIN2 SS

#define MOTOR_BIN1 WB_IO3

#define MOTOR_BIN2 MOSI

#define MOTOR_SLEEP WB_IO6

void setup()

{

// Enable DRV8833 output.

pinMode(MOTOR_SLEEP, OUTPUT);

digitalWrite(MOTOR_SLEEP, HIGH);

pinMode(MOTOR_AIN1, OUTPUT);

pinMode(MOTOR_AIN2, OUTPUT);

pinMode(MOTOR_BIN1, OUTPUT);

pinMode(MOTOR_BIN2, OUTPUT);

}

void loop()

{

analogWrite(MOTOR_AIN2, 0);

analogWrite(MOTOR_BIN2, 0);

for(uint8_t i = 0 ;i < 255 ;i++ )

{

analogWrite(MOTOR_AIN1, i);

analogWrite(MOTOR_BIN1, i);

delay(50);

}

delay(100);

for(uint8_t i = 255 ;i > 0 ;i-- )

{

analogWrite(MOTOR_AIN1, i);

analogWrite(MOTOR_BIN1, i);

delay(50);

}

analogWrite(MOTOR_AIN1, 0);

analogWrite(MOTOR_BIN1, 0);

for(uint8_t i = 0 ;i < 255 ;i++ )

{

analogWrite(MOTOR_AIN2, i);

analogWrite(MOTOR_BIN2, i);

delay(50);

}

delay(100);

for(uint8_t i = 255 ;i > 0 ;i-- )

{

analogWrite(MOTOR_AIN2, i);

analogWrite(MOTOR_BIN2, i);

delay(50);

}

delay(100);

}

If you experience any error in compiling the example sketch, check the updated code for the RAK4631 WisBlock Core Module that can be found on the RAK17000 Motor Driver Example WisBlock Repository.

The basic example code for stepper motor control can be found on the RAK17000 WisBlock Example Code repository as well.

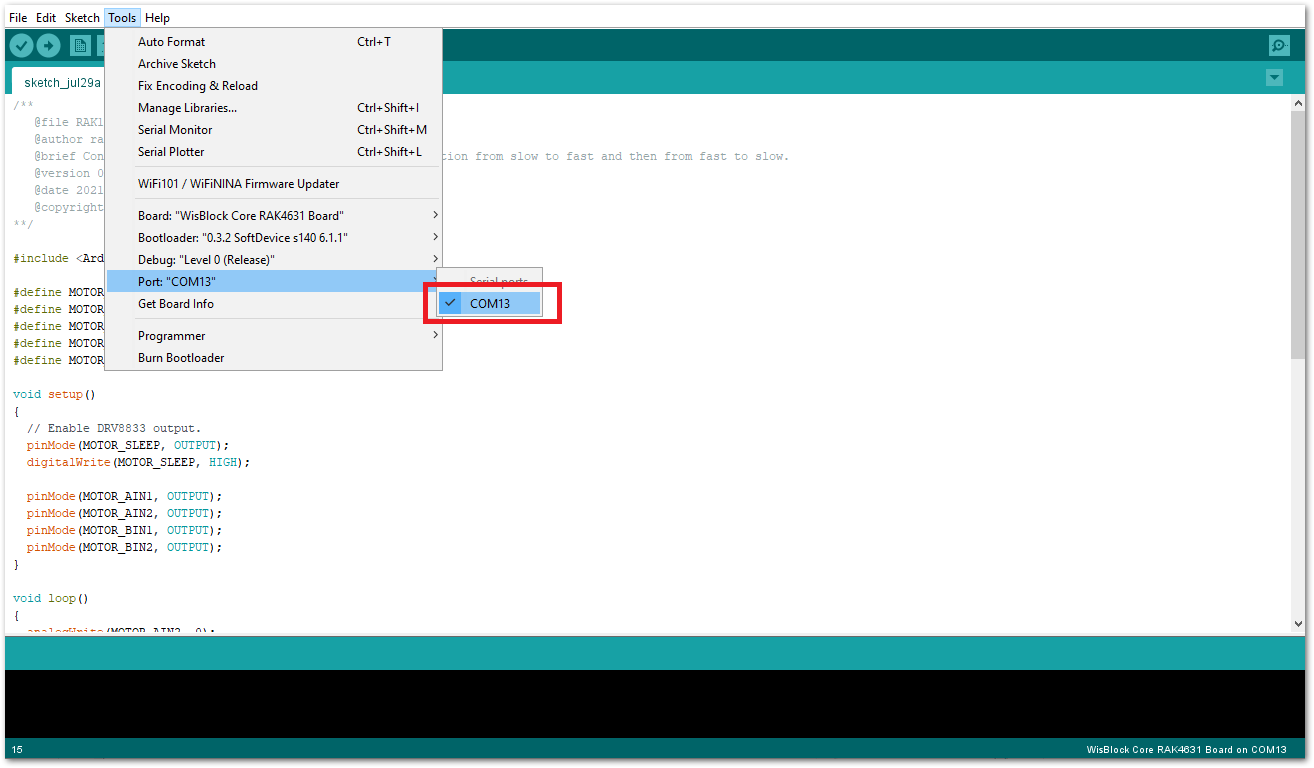

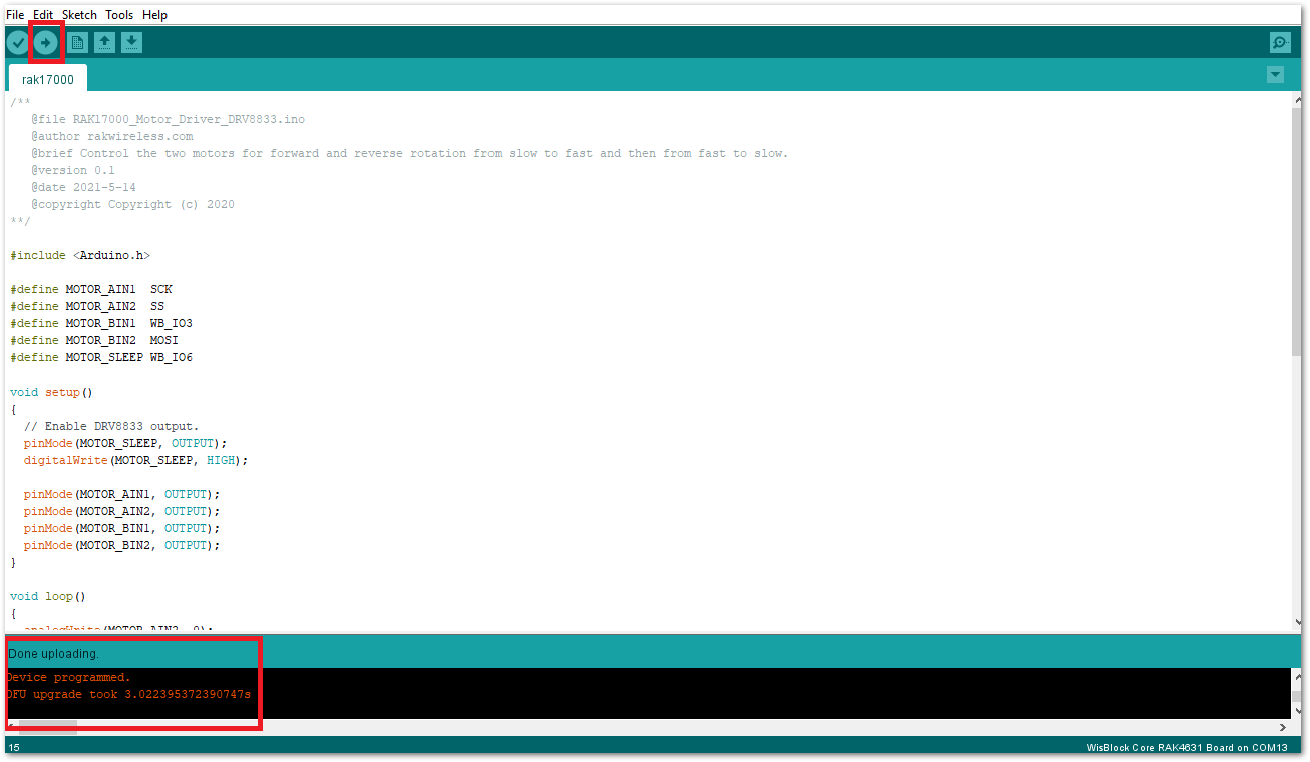

- Then you can now select the right port and upload the code, as shown in Figure 9 and Figure 10.

Figure 1: Selecting the correct Serial Port

Figure 1: Selecting the correct Serial Port Figure 1: Uploading the RAK17000 Sample code

Figure 1: Uploading the RAK17000 Sample code- When you successfully uploaded the example sketch, you'll now see that the motor will start spinning and reversing direction repeatedly.

RAK17000 in RAK11200 WisBlock Core Guide

Arduino Setup

After doing the hardware setup, this example code will work both for WisBlock battery-powered motor or an external power source. This will control the DC motors connected in channel A and channel B and make it spin clockwise then counterclockwise direction repeatedly.

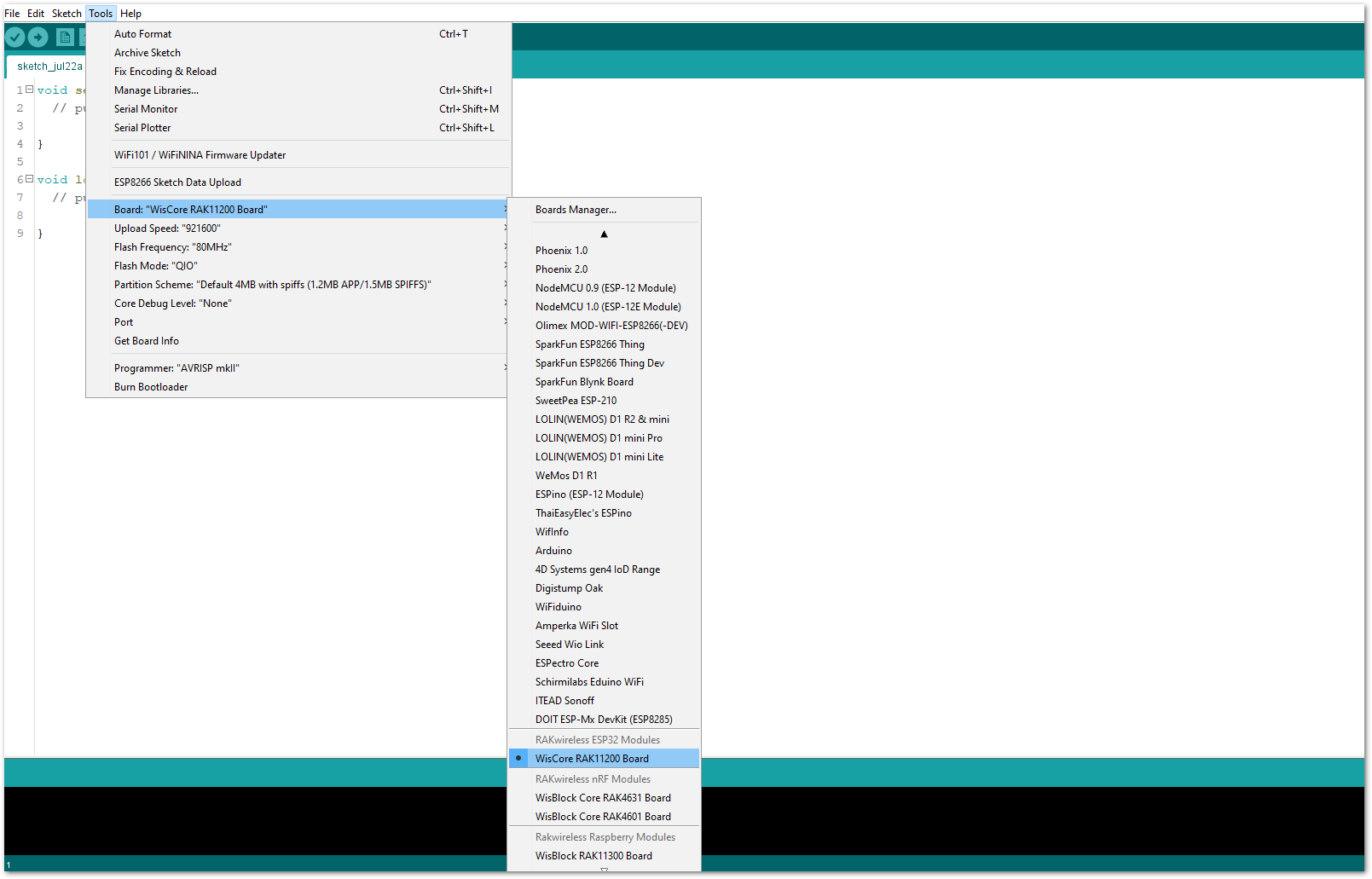

- First, you need to select the RAK11200 WisBlock Core.

Figure 1: Selecting RAK11200 as the WisBlock Core

Figure 1: Selecting RAK11200 as the WisBlock Core- Next, copy the following sample code into your Arduino IDE. This example code comes from the RAK17000 WisBlock example repository which controls two DC motors.

Click to view the code

/**

@file RAK17000_Motor_Driver_DRV8833.ino

@author rakwireless.com

@brief Control the two motors for forward and reverse rotation from slow to fast and then from fast to slow.

@version 0.1

@date 2021-5-14

@copyright Copyright (c) 2020

**/

#include <Arduino.h>

#define MOTOR_AIN1 SCK

#define MOTOR_AIN2 SS

#define MOTOR_BIN1 WB_IO3

#define MOTOR_BIN2 MOSI

#define MOTOR_SLEEP WB_IO6

// use first channel of 16 channels (started from zero)

#define LEDC_CHANNEL_0 0

#define LEDC_CHANNEL_1 1

#define LEDC_CHANNEL_2 2

#define LEDC_CHANNEL_3 3

// use 13 bit precision for LEDC timer

#define LEDC_TIMER_13_BIT 13

// use 5000 Hz as a LEDC base frequency

#define LEDC_BASE_FREQ 5000

/**

@brief Arduino like analogWrite.

*/

void ledcAnalogWrite(uint8_t channel, uint32_t value, uint32_t valueMax = 255)

{

// calculate duty, 8191 from 2 ^ 13 - 1

uint32_t duty = (8191 / valueMax) * min(value, valueMax);

// write duty to LEDC

ledcWrite(channel, duty);

}

void setup()

{

// Enable DRV8833 output.

pinMode(MOTOR_SLEEP, OUTPUT);

digitalWrite(MOTOR_SLEEP, HIGH);

ledcSetup(LEDC_CHANNEL_0, LEDC_BASE_FREQ, LEDC_TIMER_13_BIT); // Set channel 0

ledcSetup(LEDC_CHANNEL_1, LEDC_BASE_FREQ, LEDC_TIMER_13_BIT); // Set channel 1

ledcSetup(LEDC_CHANNEL_2, LEDC_BASE_FREQ, LEDC_TIMER_13_BIT); // Set channel 2

ledcSetup(LEDC_CHANNEL_3, LEDC_BASE_FREQ, LEDC_TIMER_13_BIT); // Set channel 3

ledcAttachPin(MOTOR_AIN1, LEDC_CHANNEL_0);

ledcAttachPin(MOTOR_AIN2, LEDC_CHANNEL_1);

ledcAttachPin(MOTOR_BIN1, LEDC_CHANNEL_2);

ledcAttachPin(MOTOR_BIN2, LEDC_CHANNEL_3);

}

void loop()

{

ledcAnalogWrite(LEDC_CHANNEL_1, 0);

ledcAnalogWrite(LEDC_CHANNEL_3, 0);

for(uint8_t i = 0 ;i < 255 ;i++ )

{

ledcAnalogWrite(LEDC_CHANNEL_0, i);

ledcAnalogWrite(LEDC_CHANNEL_2, i);

delay(50);

}

delay(100);

for(uint8_t i = 255 ;i > 0 ;i-- )

{

ledcAnalogWrite(LEDC_CHANNEL_0, i);

ledcAnalogWrite(LEDC_CHANNEL_2, i);

delay(50);

}

ledcAnalogWrite(LEDC_CHANNEL_0, 0);

ledcAnalogWrite(LEDC_CHANNEL_2, 0);

for(uint8_t i = 0 ;i < 255 ;i++ )

{

ledcAnalogWrite(LEDC_CHANNEL_1, i);

ledcAnalogWrite(LEDC_CHANNEL_3, i);

delay(50);

}

delay(100);

for(uint8_t i = 255 ;i > 0 ;i-- )

{

ledcAnalogWrite(LEDC_CHANNEL_1, i);

ledcAnalogWrite(LEDC_CHANNEL_3, i);

delay(50);

}

delay(100);

}

If you experience any error in compiling the example sketch, check the updated code for the RAK11200 WisBlock Core Module that can be found on the RAK17000 Motor Driver Example WisBlock Repository.

The basic example code for stepper motor control can be found on the RAK17000 WisBlock Example Code repository as well.

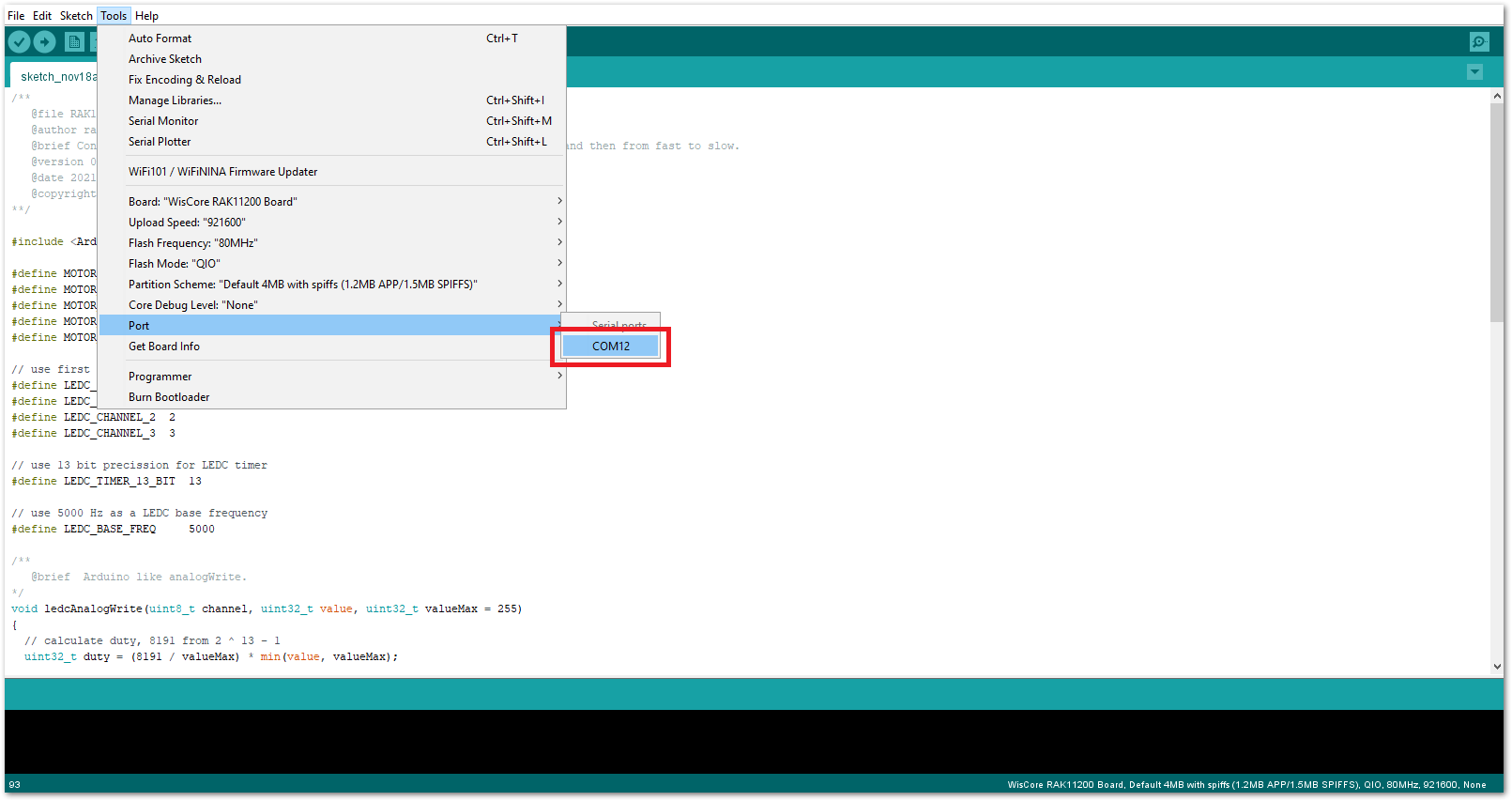

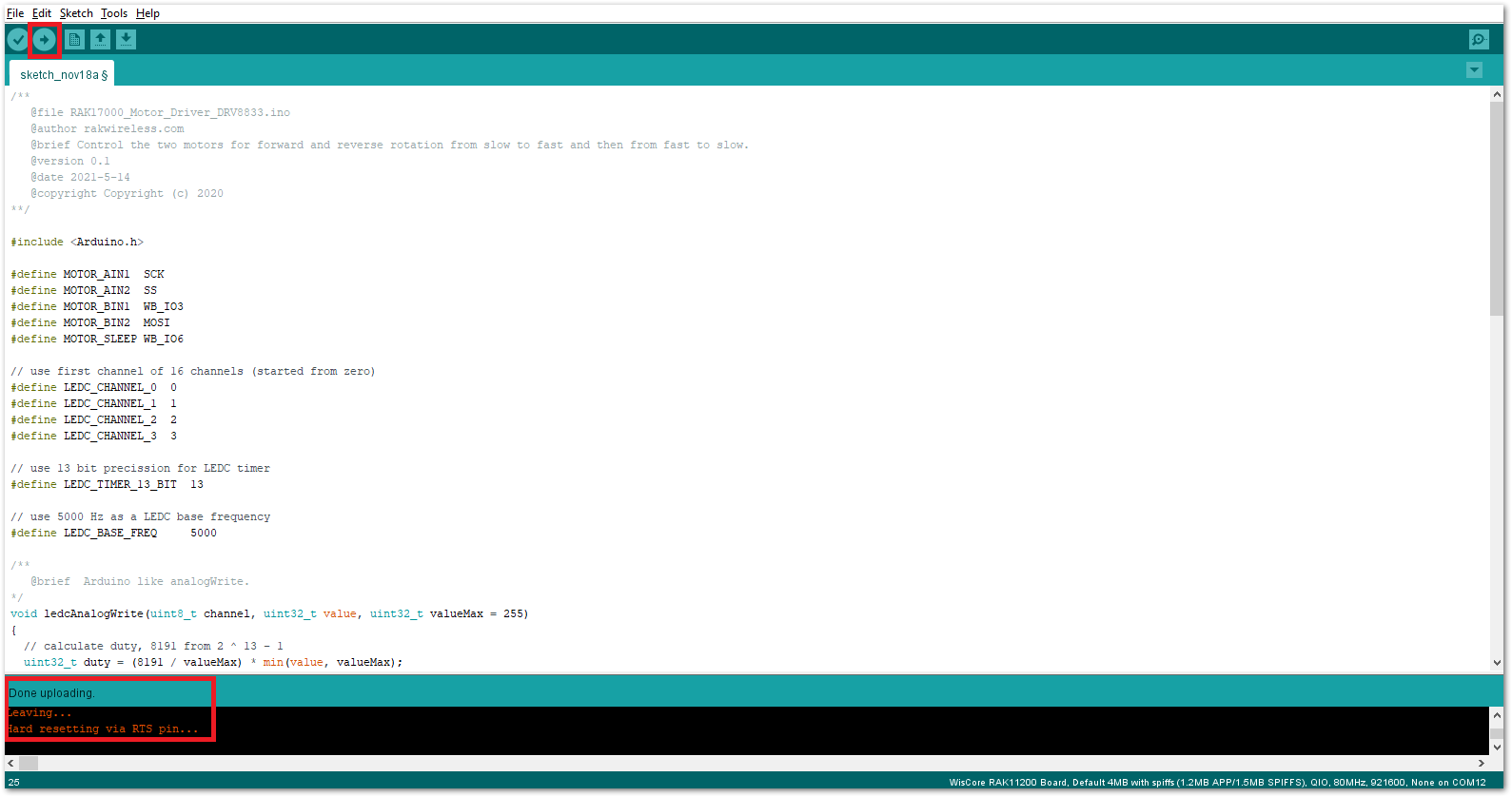

- Then you can now select the right port and upload the code, as shown in Figure 12 and Figure 13.

RAK11200 requires the Boot0 pin to be configured properly first before uploading. If not done properly, uploading the source code to RAK11200 will fail. Check the full details on the RAK11200 Quick Start Guide.

Figure 1: Selecting the correct Serial Port

Figure 1: Selecting the correct Serial Port Figure 1: Uploading the RAK17000 Sample code

Figure 1: Uploading the RAK17000 Sample code- When you successfully uploaded the example sketch, you'll now see that the motor will start spinning and reversing direction repeatedly.

RAK17000 in RAK11310 WisBlock Core Guide

Arduino Setup

After doing the hardware setup, this example code will work both for WisBlock battery-powered motor or an external power source. This will control the DC motors connected in channel A and channel B and make it spin clockwise then counterclockwise direction repeatedly.

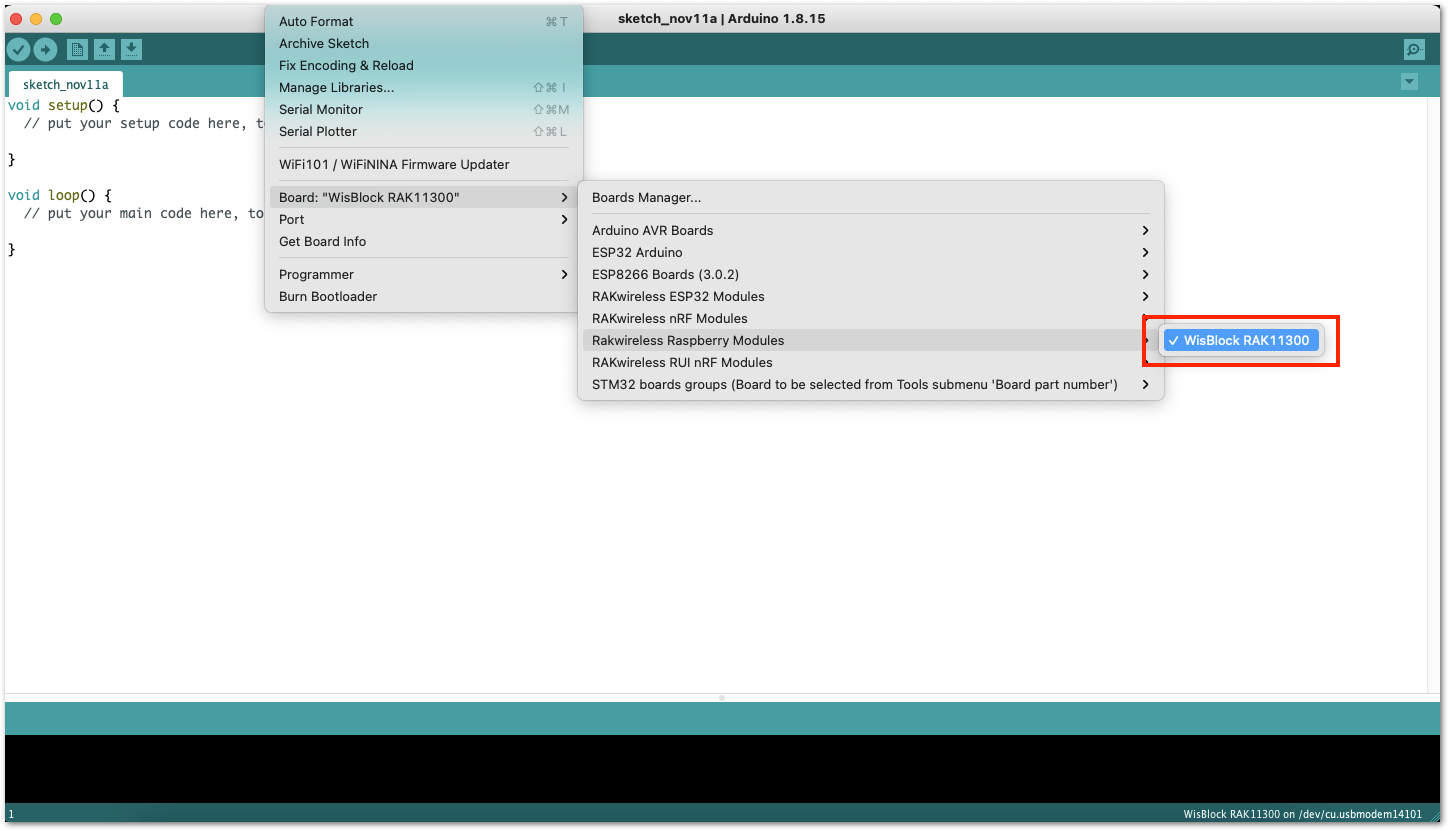

- First, you need to select the RAK11310 WisBlock Core.

Figure 1: Selecting RAK11310 as the WisBlock Core

Figure 1: Selecting RAK11310 as the WisBlock Core- Next, copy the following sample code into your Arduino IDE. This example code comes from the RAK17000 WisBlock example repository which controls two DC motors.

Click to view the code

/**

@file RAK17000_Motor_Driver_DRV8833.ino

@author rakwireless.com

@brief Control the two motors for forward and reverse rotation from slow to fast and then from fast to slow.

@version 0.1

@date 2021-5-14

@copyright Copyright (c) 2020

**/

#include <Arduino.h>

#define MOTOR_AIN1 SCK

#define MOTOR_AIN2 SS

#define MOTOR_BIN1 WB_IO3

#define MOTOR_BIN2 MOSI

#define MOTOR_SLEEP WB_IO6

void setup()

{

// Enable DRV8833 output.

pinMode(MOTOR_SLEEP, OUTPUT);

digitalWrite(MOTOR_SLEEP, HIGH);

pinMode(MOTOR_AIN1, OUTPUT);

pinMode(MOTOR_AIN2, OUTPUT);

pinMode(MOTOR_BIN1, OUTPUT);

pinMode(MOTOR_BIN2, OUTPUT);

}

void loop()

{

analogWrite(MOTOR_AIN2, 0);

analogWrite(MOTOR_BIN2, 0);

for(uint8_t i = 0 ;i < 255 ;i++ )

{

analogWrite(MOTOR_AIN1, i);

analogWrite(MOTOR_BIN1, i);

delay(50);

}

delay(100);

for(uint8_t i = 255 ;i > 0 ;i-- )

{

analogWrite(MOTOR_AIN1, i);

analogWrite(MOTOR_BIN1, i);

delay(50);

}

analogWrite(MOTOR_AIN1, 0);

analogWrite(MOTOR_BIN1, 0);

for(uint8_t i = 0 ;i < 255 ;i++ )

{

analogWrite(MOTOR_AIN2, i);

analogWrite(MOTOR_BIN2, i);

delay(50);

}

delay(100);

for(uint8_t i = 255 ;i > 0 ;i-- )

{

analogWrite(MOTOR_AIN2, i);

analogWrite(MOTOR_BIN2, i);

delay(50);

}

delay(100);

}

If you experience any error in compiling the example sketch, check the updated code for the RAK11310 WisBlock Core Module that can be found on the RAK17000 Motor Driver Example WisBlock Repository.

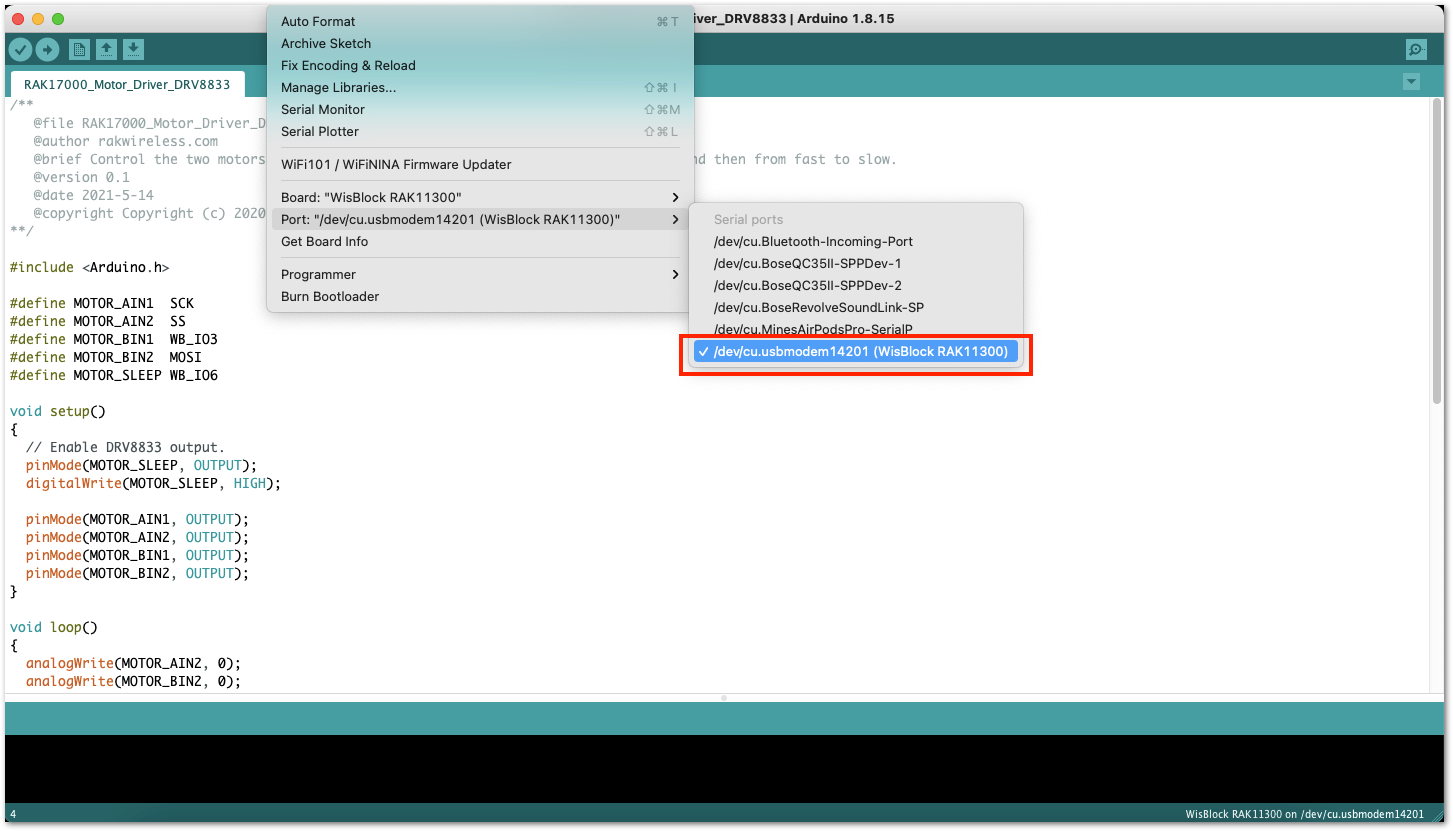

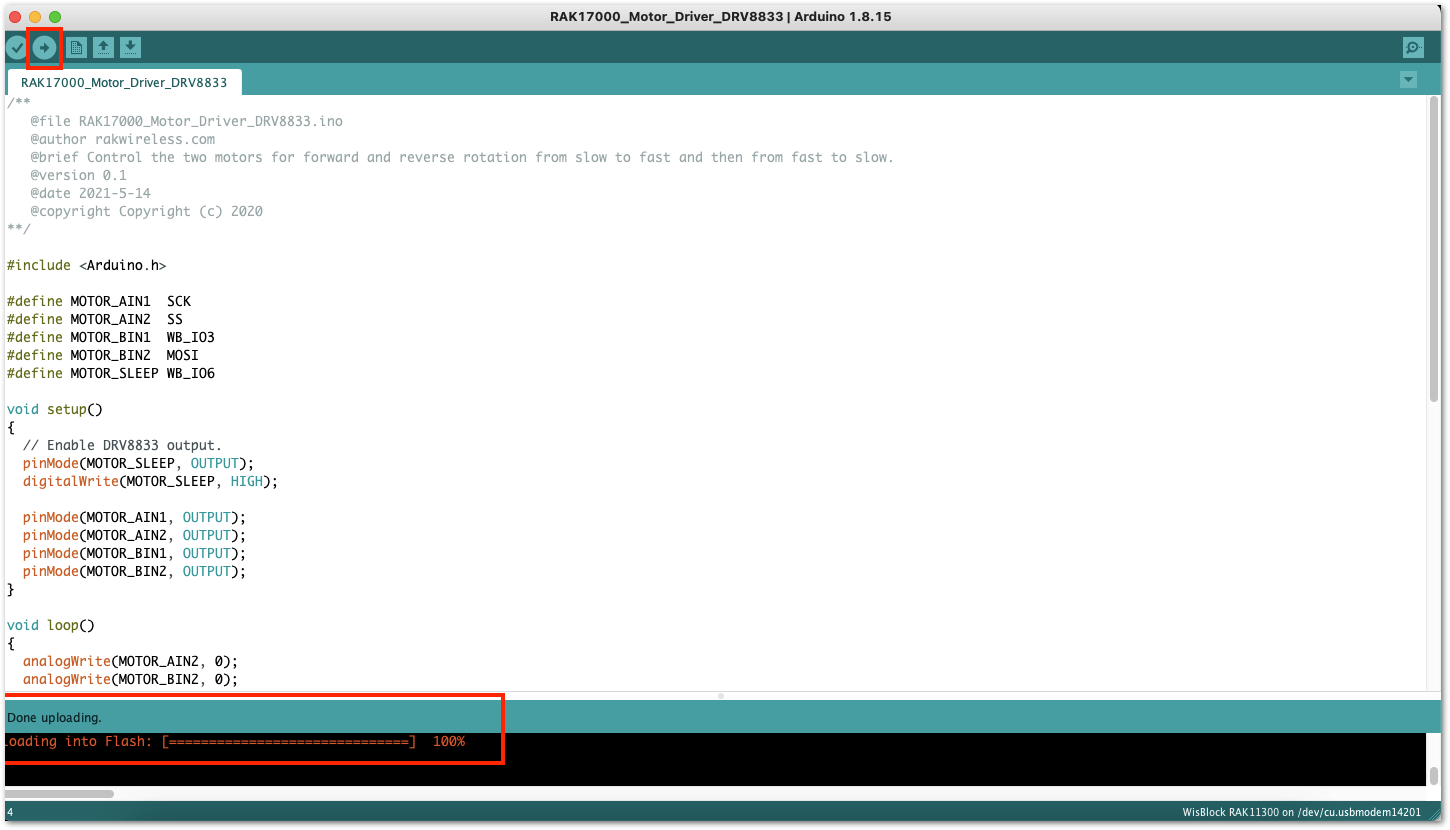

- Then you can now select the right port and upload the code, as shown in Figure 15 and Figure 16.

Figure 1: Selecting the correct Serial Port

Figure 1: Selecting the correct Serial Port Figure 1: Uploading the RAK17000 Sample code

Figure 1: Uploading the RAK17000 Sample code- When you successfully uploaded the example sketch, you'll now see that the motor will start spinning and reversing direction repeatedly.