RS485 Configuration

RS485 is a robust serial communication interface widely used in industrial environments for long-distance, noise-resistant data transmission. In IO.Box, it is used to connect Modbus RTU slave devices (such as power meters, sensors, and PLC I/O modules) for periodic data collection and remote control through polling tasks.

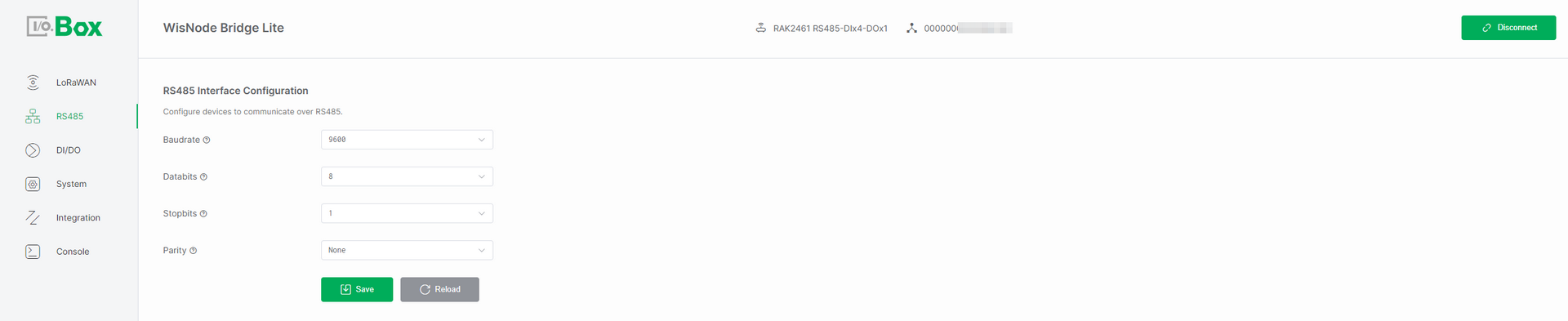

RS485 Interface Configuration

RS485 interface configuration defines the physical-layer serial parameters used between IO.Box and a Modbus RTU device. In the RS485 Interface Configuration menu, you can configure these parameters to match the RS485 communication settings of the connected device. The configuration takes effect after clicking Save.

Figure 1: RS485 Interface configuration

Figure 1: RS485 Interface configuration-

Baudrate: The communication speed on the RS485 bus, measured in bits per second (bps). Select a baudrate that matches the speed required by your connected device.

-

Databits: The number of data bits in each character. Choose either 7 or 8 bits based on the protocol requirements specified by your device.

-

Stopbits: The number of bits that signal the end of a character frame. Configure this as 1 or 2 stop bits, depending on your device's data transmission protocol.

-

Parity: An error-checking method for serial communication. Select the parity setting that matches your device's requirements from the available options:

-

None (no parity check)

-

Even (even parity check)

-

Odd (odd parity check)

-

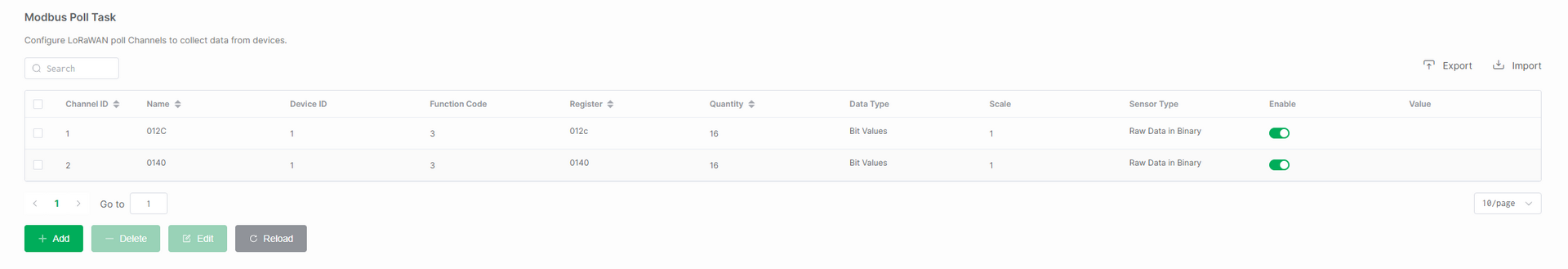

Modbus Poll Task

Modbus Poll Task configuration is used to manage Modbus communication. Once enabled, IO.Box can automatically read sensor data or write control commands, making it suitable for industrial automation, data acquisition, and device monitoring scenarios.

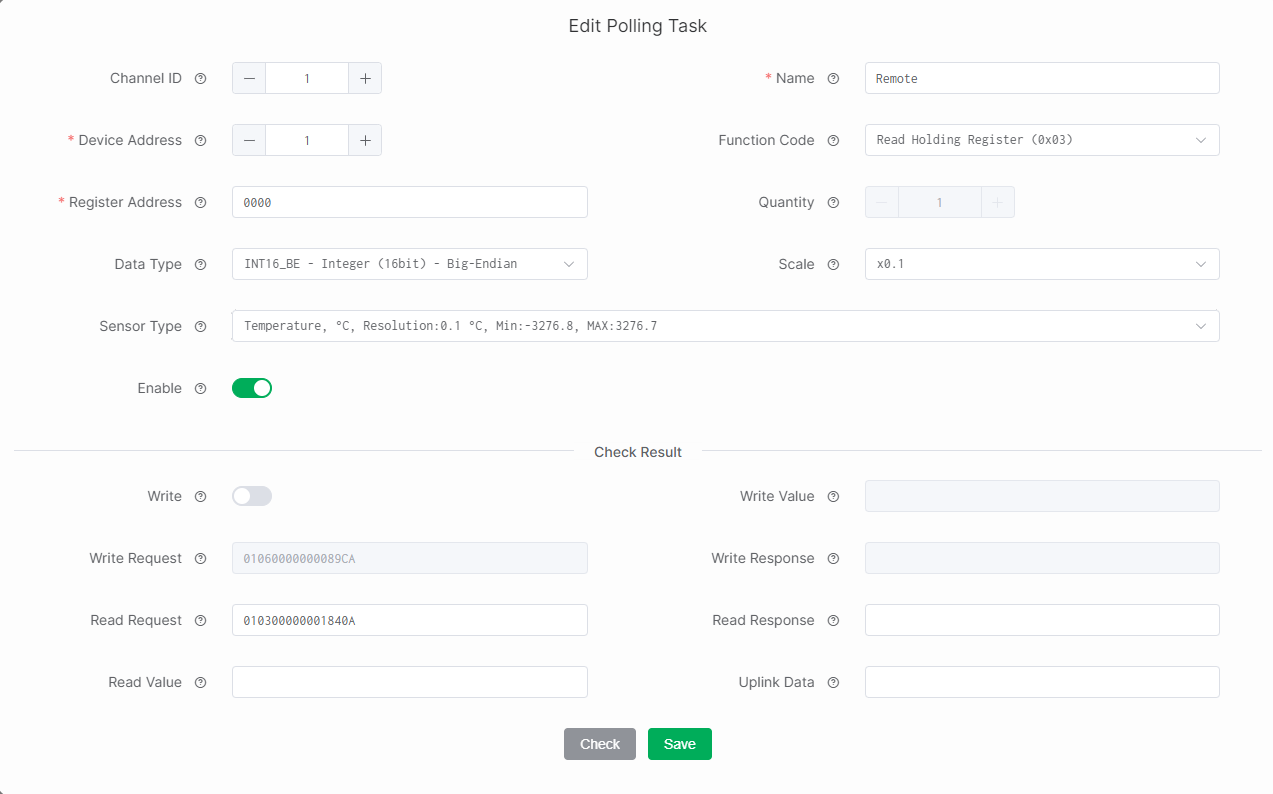

Add Modbus Poll Task

In the Modbus Poll Task menu, click + Add to create a new polling task. Configure the parameters below according to the datasheet/manual of the connected device. After setting them up, click Save to activate the task.

Figure 1: Poll Task configuration 1

Figure 1: Poll Task configuration 1-

Channel ID: Manually assigned by the user to distinguish different data streams or communication channels. This ID is included in the device’s uplink data to indicate the task.

-

Name: Custom name. Length: 4–15.

-

Device Address: The unique address of the connected device on the RS485 bus, obtained from the device manual. If the manual provides the value in hexadecimal, convert it to decimal before entering. Range: 1–254.

-

Function Code: Specifies the task's Modbus operation type (read or write), obtained from the device manual. Common function codes:

-

Read Holding Register (0x03): Read/write configurable parameters (set points, thresholds).

-

Read Input Register (0x04): Read real-time measurements (sensor readings), read-only.

-

Read Coil (0x01): Read digital output states (relay/switch), readable and writable.

-

Read Discrete Input (0x02): Read digital input states (switch/alarm), read-only.

-

-

Register Address: The target register or coil address used in the Modbus request. The value is obtained from the device manual and must be entered in hexadecimal format such as

0009.NOTERegister Address uses 0-based addressing (offset starts from 0). If your device manual uses logical addresses such as

4xxxx, calculate the decimal offset first, then convert to hex.

Example: device manual shows40010.-

Decimal offset =

40010 - 40001 = 9. -

Register Address (hex) =

0009.

When you enable the Use Reference Address option on the Modbus Poll Task page, the Register Address field must be entered using the logical address format, such as

4xxxx. Figure 1: Poll Task configuration2

Figure 1: Poll Task configuration2 -

-

Quantity: The number of registers or coils to read or write, determined by the selected Data Type. Refer to Table 1 for details.

-

Data Type: Defines how IO.Box parses the Modbus response payload into a usable value. The value corresponds to the selected registers or coils Quantity. Refer to Table 1 below for the specific mapping.

Table 1. Data Type vs. Quantity Correspondence Table

This table follows the common Modbus convention: one register = 16 bits (2 bytes). Always confirm with your device manual if it uses special packing.

Data Type Data Size Quantity (Registers) Notes INT16_BE 16-bit 1 Integer 16bit Big Endian UINT16_BE 16-bit 1 Unsigned Integer 16bit Big Endian INT16_LE 16-bit 1 Integer 16bit Little Endian UINT16_LE 16-bit 1 Unsigned Integer 16bit Little Endian INT32_BE (ABCD) 32-bit 2 Signed Integer 32bit Big Endian UINT32_BE (ABCD) 32-bit 2 Unsigned Integer 32bit Big Endian INT32 (CDAB) 32-bit 2 Signed Integer 32bit UINT32 (CDAB) 32-bit 2 Unsigned Integer 32bit INT32_LE (DCBA) 32-bit 2 Signed Integer 32bit Little Endian UINT32_LE (DCBA) 32-bit 2 Unsigned Integer 32bit Little Endian Float (ABCD) 32-bit 2 Big Endian Float (CDAB) 32-bit 2 Mixed endian Float (DCBA) 32-bit 2 Little Endian Bit Values varies Manually configurable Register or byte parsed as bit level fields implementation dependent Modbus ADU varies Manually configurable Raw frame parsing quantity depends on what you need to capture -

Scale: To adjust the raw data from the Modbus response to the desired units. For example, to convert kilograms to grams, set the scale to X1000.

-

Sensor Type: Select the unit or category that best matches your slave device output (used for correct interpretation and presentation).

-

Interval: The frequency at which the device sends Modbus requests (polling period). Range: 5 to 86400 seconds.

-

Enable: Enable or disable the task. When disabled, IO.Box will not collect data or write values for this task.

Check Result

After you finish editing a poll task, click Check to validate whether:

-

The configuration parameters are correct.

-

The device can communicate successfully, and the response can be parsed into the expected value and uplink payload format.

If there are no issues during the check, click Save to save the configuration.

-

Write: Enables writing to device registers or coils. Configurable when Function Code is Read Holding Register (0x03) or Read Coil (0x01).

-

Write/Read Request: Displays the Modbus command generated from the polling task configuration, based on the selected settings, which is used to communicate with the Modbus device.

-

Write/Read Response: The response returned by the slave for the request, indicates whether the operation succeeded and contains returned data.

-

Write Value: The value written to the specified register or coil.

-

Read Value: The parsed value extracted from the response according to the above configuration.

-

Uplink Data: The formatted payload that IO.Box will send to the server, based on your task configuration.

Edit Modbus Poll Task

To modify an existing Poll Task, follow these steps:

-

Go to the Modbus Poll Task menu.

-

Select the target Poll Task from the list and click Edit.

-

Update the required fields, such as Interval, Register Address, Quantity, and Data Type.

-

Click Save to apply the changes.

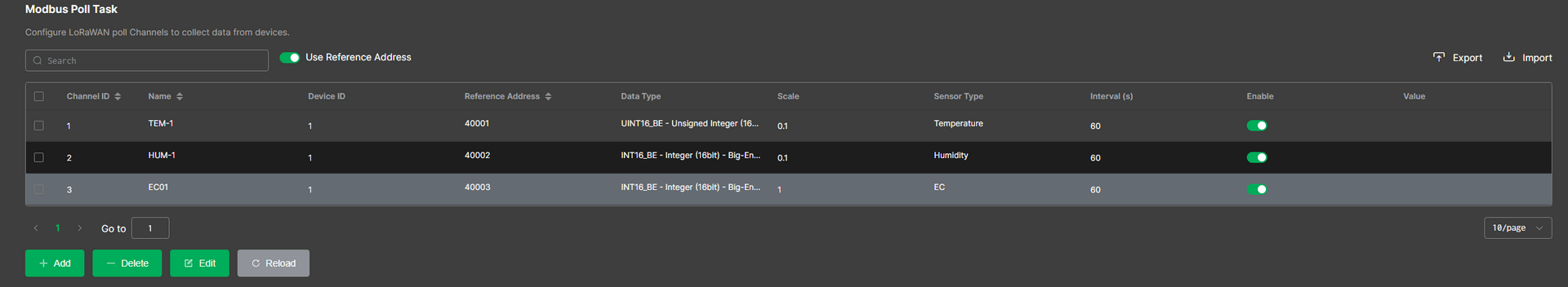

Import/Export Poll Task

Figure 1: Import or Export Poll Task

Figure 1: Import or Export Poll TaskImport Poll Task

The Import function is used to quickly apply a set of predefined polling tasks to a device, without the need to create them manually one by one. Typical use cases include batch deployment and device replacement.

In the Modbus Poll Task menu, click Import, then select and upload the Modbus Poll Task template file you wish to import.

Export Poll Task

The Export function is used to back up the polling task configuration for later reuse. It is useful for scenarios like saving templates and version management.

In the Modbus Poll Task menu, click Export to download the currently configured Modbus Poll Task to a specified path.

Delete Modbus Poll Task

If you want to delete a polling task, go to the Modbus Poll Task menu, select the target Poll Task, click Delete, and then click OK to remove the task.

After deletion, the device will stop polling those registers, and the corresponding uplink data will no longer be generated for that Channel ID.